NxHE Series Two-Stage

125-350HP / 90-260kW

FS-CURTIS’s most energy-efficient air compressor to date, the NxHE Series compressors use patented two-stage airend technology to provide efficient operation with outstanding durability and offer the lowest life-cycle cost of any compressor on the market.

Compared to single-stage compressors, a two-stage is much closer to isothermal compression. This is achieved by injection of fresh oil between the stages which reduces the inlet temperature to the second stage.

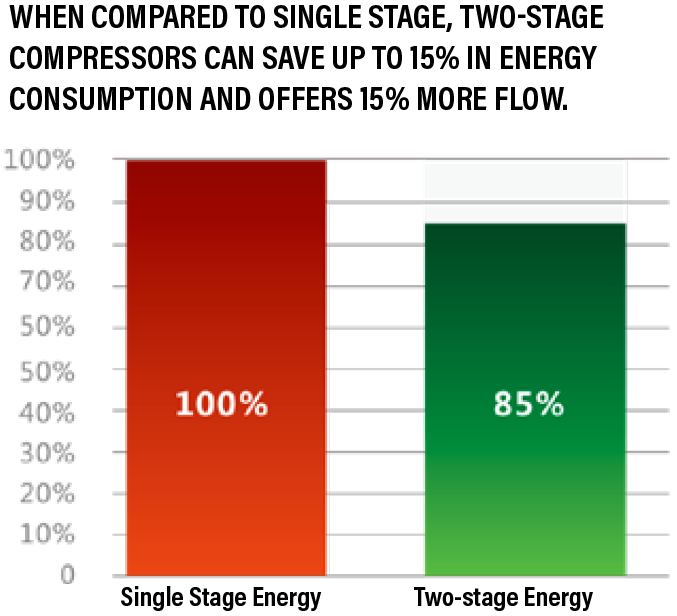

Two-stage air compressors are closer to the ideal isothermal compression:

- Reduced leakage increases volumetric efficiency

- Saves 10-15% of energy compared to single-stage compressors

- Increases flow 10-15% compared to single-stage compressors

- Lower pressure differential increases efficiency and reliability

- Lowest life-cycle cost of any compressor on the market

Two-Stage Models: NxHE-90, NxHE-110, NxHE-132, NxHE-160, NxHE-185, NxHE-200, NxHE-220, NxHE-260

Click Here For Maintenance Kits

Compared to single stage compressors, a two-stage is much closer to isothermal compression. This is

achieved by injection of fresh oil between the stages which reduces the inlet temperature to the second

stage. This lower inlet temperature increases efficiency by reducing the compression ratio between

the stages. In addition, leaage between the rotor seals is significantly reduced resulting in

outstanding volumetric efficiency.

• Two-stage air compressors are closer to the ideal isothermal compression

• Reduced leakage increases volumetric efficiency

• Saves 10-15% of energy compared to single stage compressors

• Increases flow 10-15% compared to single stage compressors

• Lower pressure differential increases efficiency and reliability

• Low heat load

• Easy maintenance and service

• Lowest life-cycle cost of any compressor on the market

• Two-stage air compressors are closer to the ideal isothermal compression

• Reduced leakage increases volumetric efficiency

• Saves 10-15% of energy compared to single stage compressors

• Increases flow 10-15% compared to single stage compressors

• Lower pressure differential increases efficiency and reliability

• Low heat load

• Easy maintenance and service

• Lowest life-cycle cost of any compressor on the market

iCommand Controller

iCommand ControllerWith the optional iCommand-Touch, a full-color screen displays graphs which capture and track factual, real-time air usage by the hour, day, week and month. Historical data can be retrieved at any time at the touch of the screen. Data trending keeps your finger on the pulse of your entire compressed air system. Continuously tracks pressure, temperature, air quantity and usage to easily diagnose and optimize your plant’s air system.

• Simple Touchscreen Control

• Intuitive Navigation

• Capture Real-time and Historical Data Trending

• Precisely delivers compressed air to usage

eCOOL® Technology

Compressors generate heat. FS-Curtis’ exclusive eCOOL technology provides protection from heat and reduces thermal stress.

By combining smart compressor layout with intelligent component selection, eCOOL technology maximizes cooling airflow for greater energy efficiency, improved reliability and increases service life up to 50% longer for motors and electrical components and up to 30-50% longer for bearings, hoses and seals.

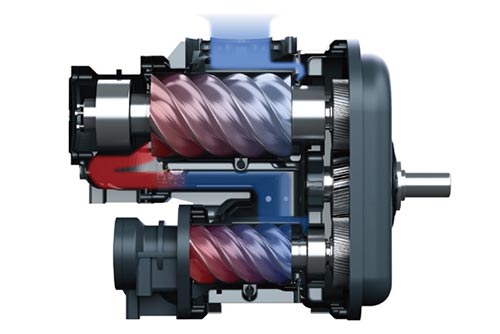

Energy-efficient Two-stage Aairend

Energy-saving and Eco-friendly

• Premium Efficiency TEFC (IP55 Class F) motor protects compressor from harsh environment

• Patented airend design integrates the first and second stage rotors into one airend

• Oil is injected between the first and second stages to cool the air and optimize efficiency

• Splitting the compression cycle into Two-stages reduces the axial and thrust loading to which improves service life of airend and bearings

• Two-stage compression significantly reduces noise

Effectively integrated overall design

Designed for low cost of ownership, easy service & little down time

• Safe, efficient air filter system

• Independent bearing lubrication

• High efficiency, easy-to-maintain oil separator

• IE3 high efficiency motor

• End face sealed to prevent leakage

• Connections utilize o-ring face seals for leak--free performance

• Asbestos-free gaskets protect operator health

NXGEN WARRANTY

Extended Warranty Program

All Nx products are backed by an industry leading warranty:

• Five-year major components warranty

• Ten-year airend warranty

Just register the machine online, Use only FS-Curtis Genuine Parts & Lubricants per the required maintenance schedule, and you will have peace of mind knowing that your machine is backed by the NxGEN Warranty

Extended Warranty Program

All Nx products are backed by an industry leading warranty:

• Five-year major components warranty

• Ten-year airend warranty

Just register the machine online, Use only FS-Curtis Genuine Parts & Lubricants per the required maintenance schedule, and you will have peace of mind knowing that your machine is backed by the NxGEN Warranty

Options

Call for options

Click for Larger View

Click for Larger View